Moldboard plows have been a cornerstone of agricultural practices for centuries, playing a crucial role in soil preparation and crop production. Understanding how they work and when to use them can significantly enhance your farming efficiency and yield.

Understanding Moldboard Plows

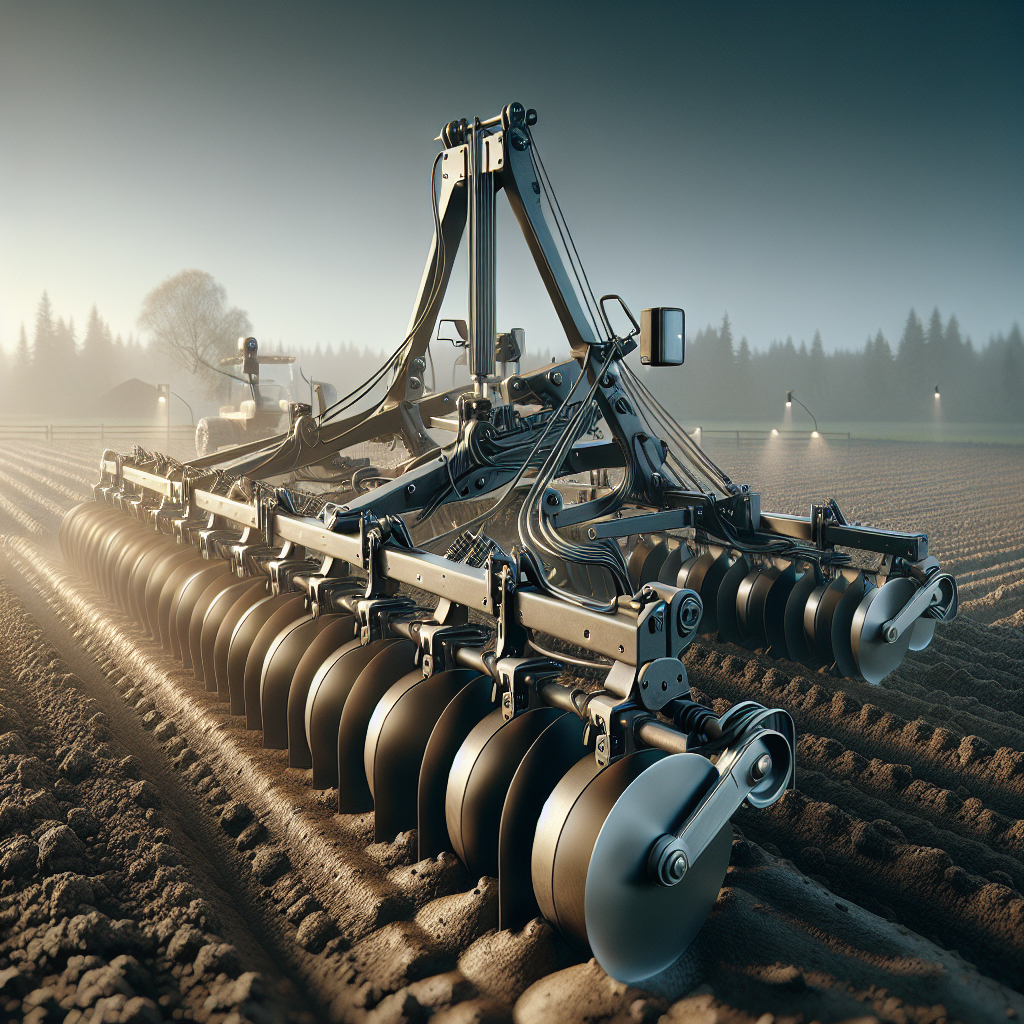

The moldboard plow is a traditional farming implement designed to turn over the upper layer of soil, bringing fresh nutrients to the surface while burying weeds and crop residues. This process not only prepares the soil for planting but also helps in controlling pests and diseases. The main components of a moldboard plow include the share, moldboard, landside, and frog. Each part plays a vital role in the plowing process.

The Share

The share is the cutting edge of the plow that slices through the soil. It is typically made of high-carbon steel to withstand the rigors of cutting through tough soil and debris. The share’s sharpness and angle are crucial for efficient plowing, as a dull or improperly angled share can lead to increased drag and reduced effectiveness.

The Moldboard

The moldboard is the curved surface that lifts and turns the soil. Its design is critical for achieving the desired soil turnover. A well-designed moldboard will create a smooth, even furrow, which is essential for subsequent planting operations. The curvature and length of the moldboard can vary depending on the type of soil and the specific plowing requirements.

The Landside

The landside is the flat, vertical surface that runs along the furrow wall, providing stability and guiding the plow through the soil. It helps to balance the plow and prevent it from veering off course. The landside also bears much of the lateral pressure exerted by the soil, making it a crucial component for maintaining straight furrows.

The Frog

The frog is the central part of the plow that connects the share, moldboard, and landside. It serves as the backbone of the plow, ensuring that all components work together seamlessly. The frog’s design and construction quality can significantly impact the plow’s overall performance and durability.

When to Use Moldboard Plows

Knowing when to use a moldboard plow is essential for maximizing its benefits and minimizing potential drawbacks. Moldboard plows are particularly effective in certain conditions and for specific purposes.

Soil Preparation

Moldboard plows are ideal for initial soil preparation, especially in fields that have not been tilled for a long time. They are excellent for breaking up compacted soil, incorporating organic matter, and creating a fine seedbed. This is particularly important for crops that require a well-aerated and nutrient-rich soil environment.

Weed and Pest Control

One of the significant advantages of using a moldboard plow is its ability to bury weeds and crop residues deeply. This helps in reducing weed pressure and disrupting the life cycles of pests and diseases. By turning over the soil, moldboard plows can effectively reduce the need for chemical herbicides and pesticides, promoting a more sustainable farming practice.

Crop Rotation

Moldboard plows are also beneficial in crop rotation systems. By turning under the residues of the previous crop, they help in preventing the buildup of pests and diseases that can affect the next crop. This is particularly important in organic farming systems where crop rotation is a key strategy for maintaining soil health and fertility.

Soil Type Considerations

The effectiveness of a moldboard plow can vary depending on the soil type. They are generally more effective in loamy and clay soils, where their ability to turn over the soil can be fully utilized. In sandy soils, however, moldboard plows may not be as effective, as the soil particles are less cohesive and may not turn over as cleanly.

Best Practices for Using Moldboard Plows

To get the most out of your moldboard plow, it’s essential to follow some best practices. These practices can help you achieve better soil preparation, reduce wear and tear on your equipment, and improve overall efficiency.

Proper Adjustment

Before starting your plowing operation, ensure that your moldboard plow is properly adjusted. This includes setting the correct depth, aligning the plow with the tractor, and ensuring that all components are in good working condition. Proper adjustment can significantly impact the quality of the furrows and the overall effectiveness of the plowing operation.

Regular Maintenance

Regular maintenance is crucial for keeping your moldboard plow in top condition. This includes sharpening the share, checking for wear and tear on the moldboard and landside, and ensuring that all bolts and connections are secure. Regular maintenance can extend the life of your plow and improve its performance.

Plowing Techniques

Using the right plowing techniques can also make a significant difference. This includes choosing the correct plowing speed, maintaining straight furrows, and avoiding overlapping passes. Proper plowing techniques can help you achieve a more uniform seedbed and reduce soil compaction.

Soil Moisture

Soil moisture levels can greatly impact the effectiveness of moldboard plowing. Plowing in overly wet conditions can lead to soil compaction and poor furrow formation, while plowing in very dry conditions can result in excessive dust and reduced soil turnover. Aim to plow when the soil is moist but not waterlogged for the best results.

Conclusion

Moldboard plows are a valuable tool in modern agriculture, offering numerous benefits for soil preparation, weed and pest control, and crop rotation. By understanding how they work and when to use them, you can enhance your farming practices and achieve better yields. Remember to follow best practices for adjustment, maintenance, and plowing techniques to get the most out of your moldboard plow.