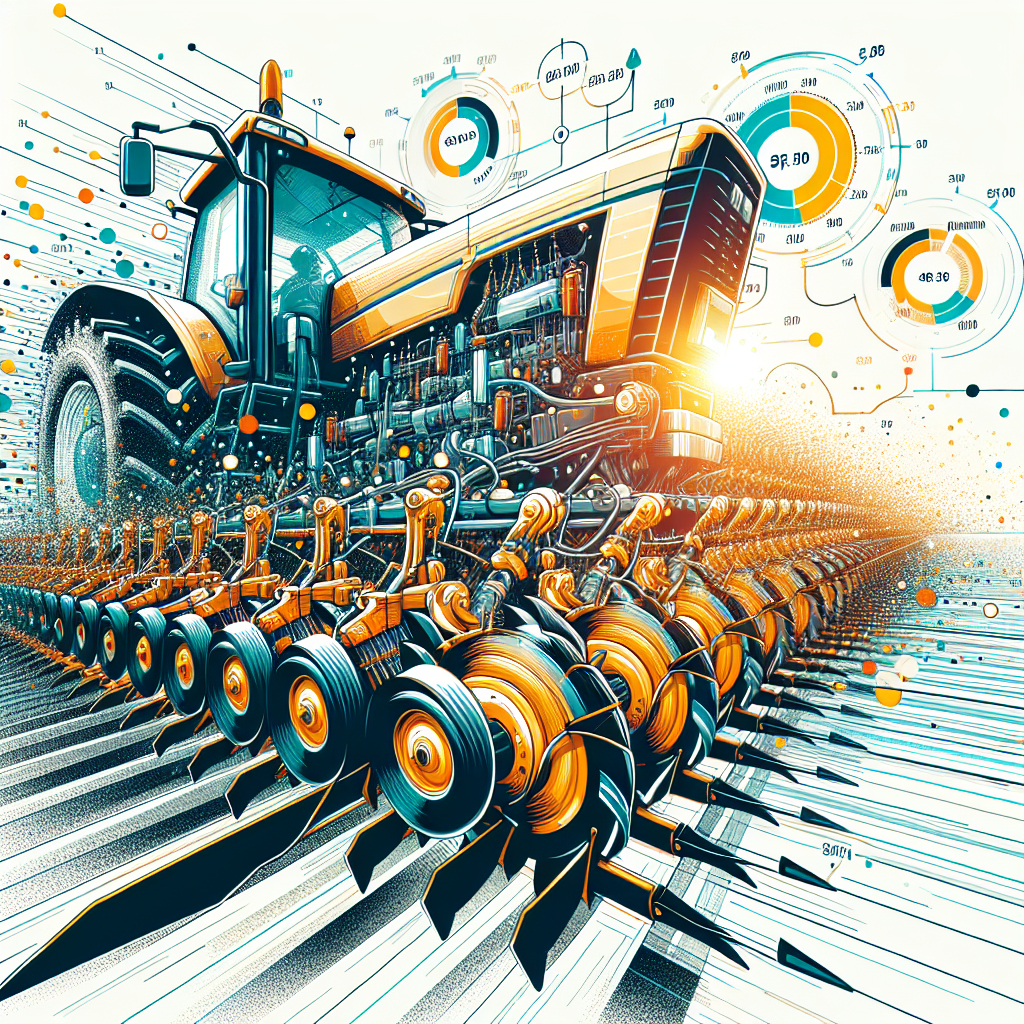

Understanding the impact of plowing speed on equipment efficiency is crucial for optimizing agricultural practices. This article delves into the various aspects of how plowing speed can influence the performance and longevity of your equipment, as well as the overall productivity of your farming operations.

The Relationship Between Plowing Speed and Equipment Wear

One of the most significant factors to consider when discussing plowing speed is its direct relationship with equipment wear and tear. Operating at higher speeds can lead to increased friction and heat, which in turn can cause more rapid degradation of plow components. This section will explore the mechanics behind this phenomenon and offer tips on how to mitigate these effects.

Friction and Heat Generation

When a plow moves through the soil at high speeds, the friction between the plowshare and the ground increases. This friction generates heat, which can weaken the metal components of the plow over time. To minimize this, it is essential to regularly lubricate moving parts and ensure that the plowshare is made of high-quality, heat-resistant materials.

Component Fatigue

High-speed plowing can also lead to component fatigue, where the repeated stress on the plow’s parts causes them to weaken and eventually fail. Regular maintenance checks and timely replacement of worn-out parts can help in reducing the risk of component fatigue. Additionally, operating at a moderate speed can significantly extend the lifespan of your equipment.

Optimizing Plowing Speed for Soil Conditions

The type of soil you are working with plays a crucial role in determining the optimal plowing speed. Different soil types have varying levels of resistance, which can affect both the efficiency of the plowing process and the condition of your equipment. This section will provide insights into how to adjust your plowing speed based on soil conditions.

Sandy Soils

Sandy soils are generally easier to plow due to their loose structure. However, plowing too quickly can cause the soil to scatter, leading to uneven plowing and potential erosion issues. A moderate speed is recommended to ensure even soil turnover and to prevent unnecessary wear on your equipment.

Clay Soils

Clay soils are denser and more challenging to plow. High-speed plowing in clay soils can lead to significant strain on your equipment, increasing the risk of damage. Slower speeds are advisable to allow the plow to cut through the dense soil more effectively, reducing the likelihood of equipment failure.

Loamy Soils

Loamy soils, which are a mix of sand, silt, and clay, offer a balanced resistance to plowing. These soils can be plowed at moderate speeds without causing excessive wear on the equipment. However, it is still essential to monitor the condition of your plow and adjust the speed as needed to maintain efficiency.

Fuel Efficiency and Plowing Speed

Another critical aspect to consider is the impact of plowing speed on fuel efficiency. Operating at higher speeds can lead to increased fuel consumption, which not only raises operational costs but also has environmental implications. This section will discuss strategies to optimize fuel efficiency while maintaining effective plowing practices.

Engine Load

High-speed plowing places a greater load on the tractor’s engine, leading to higher fuel consumption. To optimize fuel efficiency, it is essential to find a balance between speed and engine load. Operating at a speed that allows the engine to run smoothly without overexertion can help in reducing fuel usage.

Gear Selection

Choosing the right gear is crucial for maintaining fuel efficiency. Lower gears provide more power but consume more fuel, while higher gears are more fuel-efficient but may not provide enough power for effective plowing. Experimenting with different gear settings and monitoring fuel consumption can help in identifying the optimal gear for your specific plowing conditions.

Conclusion

In conclusion, the impact of plowing speed on equipment efficiency is multifaceted, affecting everything from component wear and soil conditions to fuel consumption. By understanding these factors and implementing the tips provided, you can optimize your plowing practices to enhance both the performance and longevity of your equipment. Regular maintenance, appropriate speed adjustments, and mindful fuel management are key to achieving efficient and sustainable plowing operations.